ENCLOSURE

Week 04 | 09/23/2022

A Case for Ultrasonic Distance Sensor

Enclosures are always fun to make, especially the ones that are designed for one’s own projects. The best part of each well-thought enclosure is its uniqueness, in my opinion.

This week, I customized a container / protector for one of my Physical Computing projects — an ultrasonic distance sensor, mounted on a breadboard, along with a LCD display, and of course, an Arduino, a switch, and some wires. Since it is a distance sensor, the mobility and stability of it should be high — so I also made it a detachable moving bed, with four caster wheels.

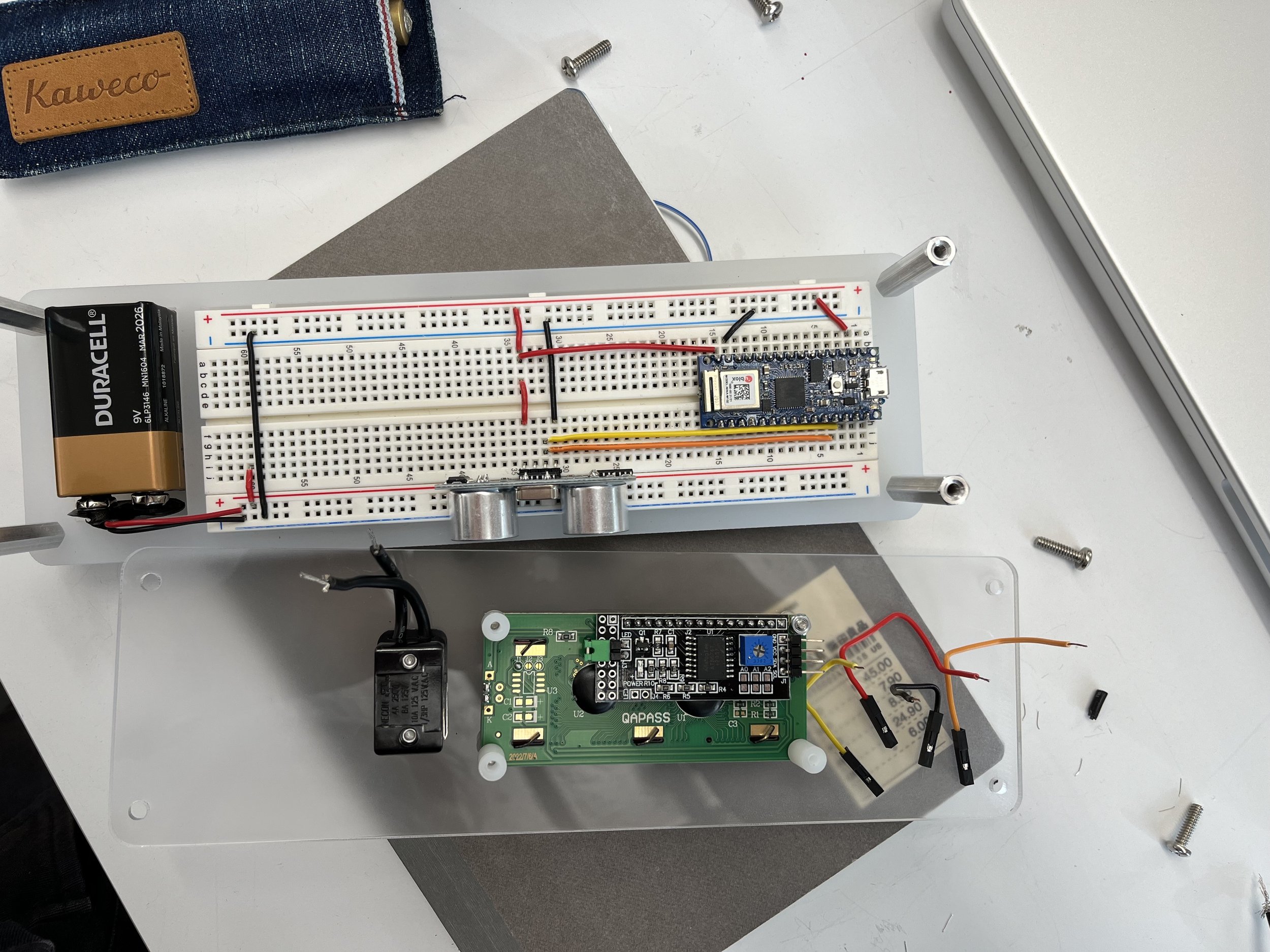

The project started with an extremely messy breadboard, with wires everywhere and LCD display and battery randomly placed on it. I spent a few hours tidying the breadboard by shortening and relocating some wires. The plan was to make a protector that has four sides open by using standoffs, hence increasing the ease of switching out parts later. Since mobility plays such an important role in a distance sensor, therefore a battery is needed. Battery is placed right next to the breadboard and it can be switched easily. All the wires are precisely measured, elegantly cut and bent afterwards, in order to make it look as tidy and simple as possible. One can easily read how the current flows — in my humble opinion, this model, in some way, might be more understandable and logical than a schematic diagram, since once can see what is really happening — direct visualization always helps.

The dimensions of the breadboard and battery are measured by a digital caliper, then a piece of holder is cut to stabilize them in x and y axes. Both the base and the holder are 1/4” acrylic, which I was lucky to find in the shop. The display and the toggle switch are screwed on the top. Thanks to the digital caliper and laser cutter, I was able to make the openings just fit. The caster wheels I bought are not the most ideal ones. Originally I was trying to put them on a base which shares the same dimension as the holder, then I found it could easily tip over due to how narrow the base is. So I updated the base and made it wider, meanwhile the screws can help position the bed.

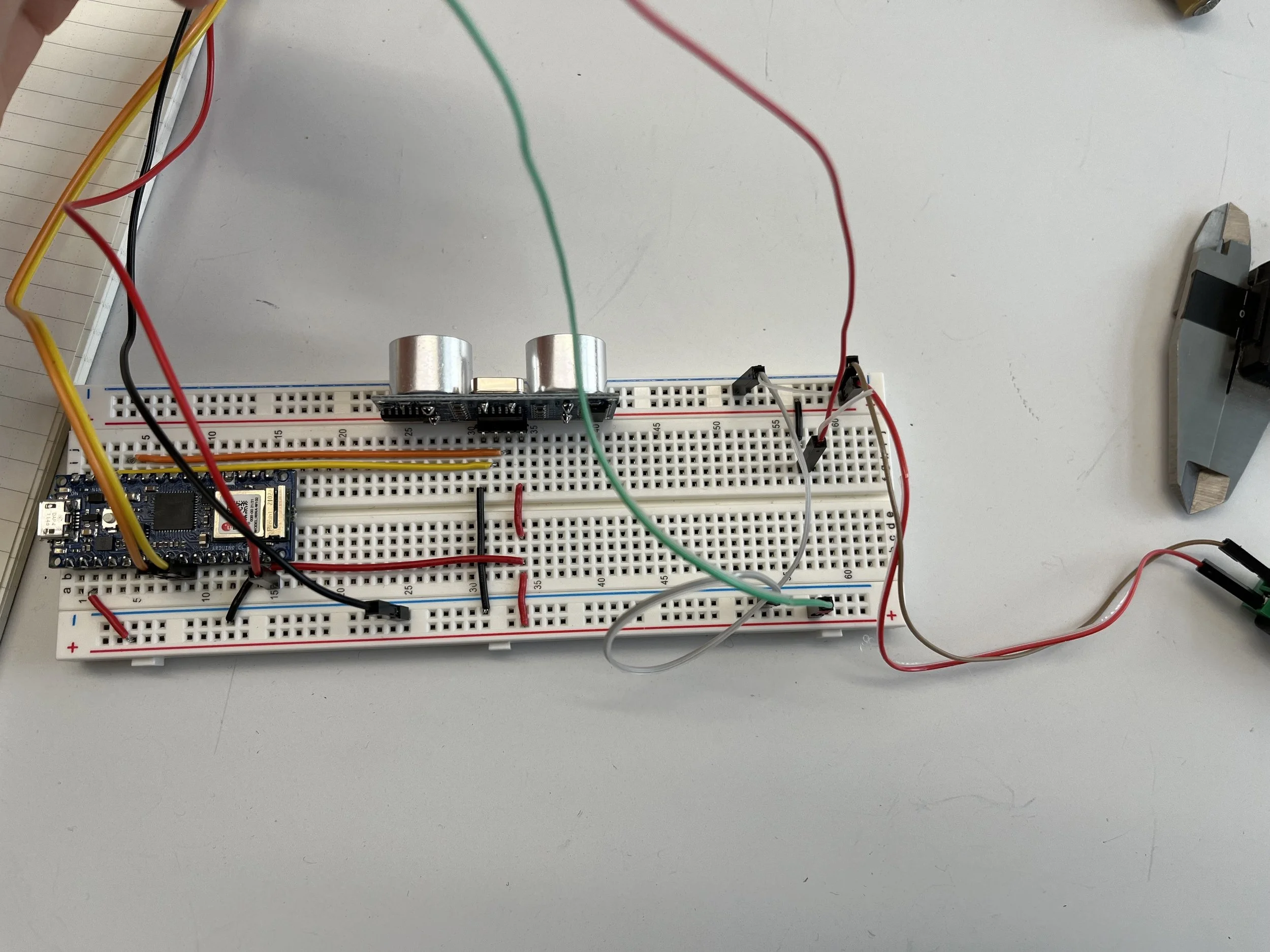

figure 1 - original setup: power from a usb

figure 2 - upgraded setup: power from a 9V battery

figure 3 - process of tidying

figure 4 - testing different outlet positions

figure 5 - holder is cut, standoffs are installed

figure 6 - battery can be easily swapped out

figure 7 - testing toggle switch and display

figure 8 - top is cut, switch and display are on

figure 9 - ready to work on the wires for the display

figure 13 - the piece is finally assembled

figure 19 - wheels are too close to each other

figure 10 - perspective view I before moving on

figure 14 - details

figure 20 - it worked, but not ideal

figure 11 - perspective view II before moving on

figure 15 - details

figure 17 - details

figure 21 - upgraded base — wider, same length

figure 23 - final product

figure 12 - wires for the switch and display cut

figure 16 - details

figure 18 - original idea for wheels

figure 22 - screws can help to position and stabilize the holder

figure 24 - final product

This project truly took me some time and a lot of brainpower, however I sincerely enjoyed the process and the outcome. Personally, I think this is one of the best projects I have ever made, including the ones from architecture school. If time permits, I would like to discover more about different tools and ways to customize containers and make my projects more complete.