TAVERN

An enclosure for Ultrasonic Distance Sensor

Fall 2022

Course: Fabrication

Instructor: Ben Light

Introduction

Creating enclosures is always an enjoyable task, especially when they are designed for one's own projects. The most unique and interesting aspect of a well-thought-out enclosure, in my opinion, is its distinctiveness.

For this particular project, I crafted a custom container/protector for one of my Physical Computing projects. It houses an ultrasonic distance sensor mounted on a breadboard, accompanied by an LCD display, an Arduino, a switch, and various wires. As it's a distance sensor, both mobility and stability are crucial considerations. Therefore, I designed it with a detachable moving bed equipped with four caster wheels.

Process

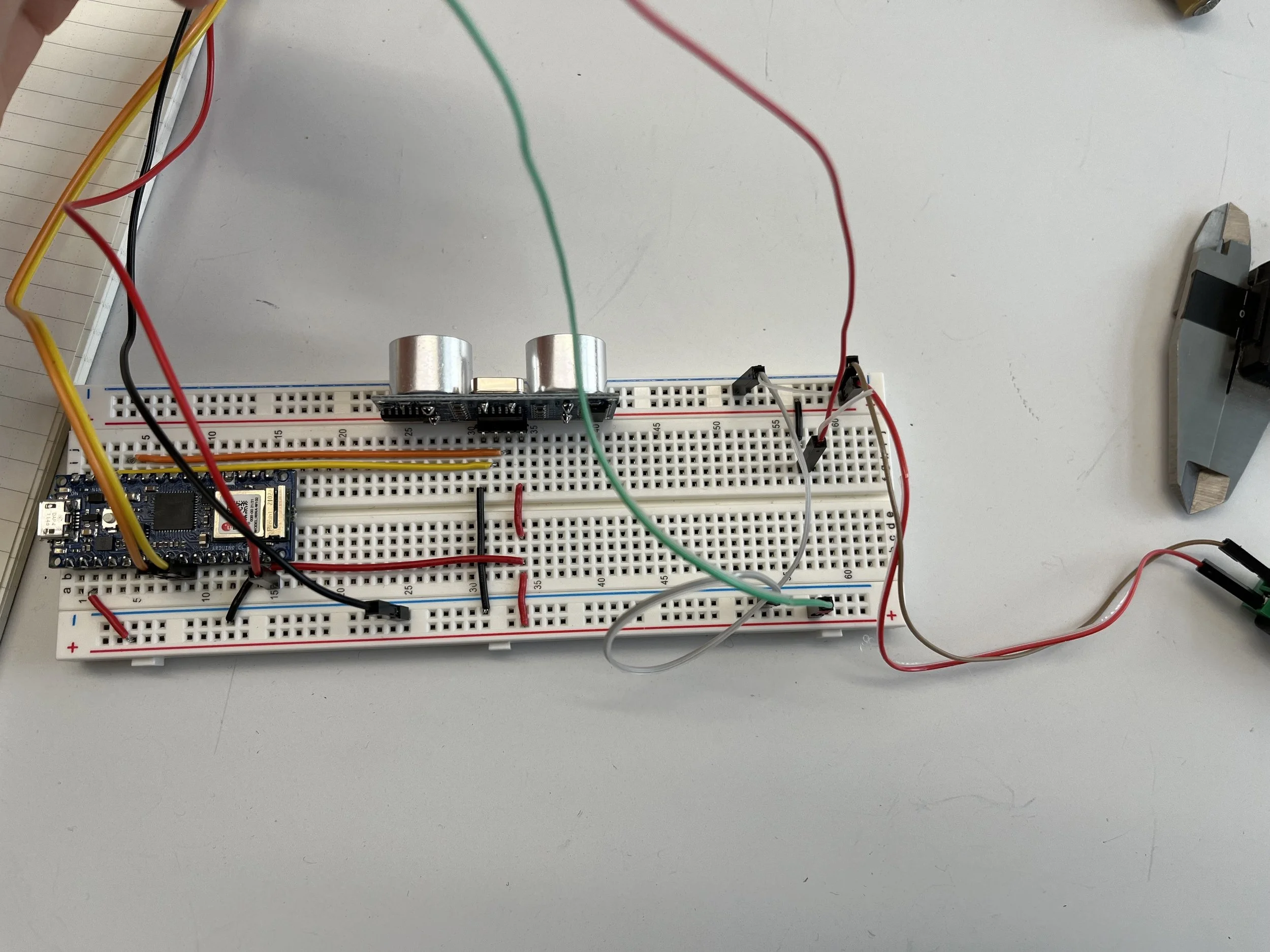

The project commenced with a chaotic breadboard, wires sprawling everywhere, and components like the LCD display and battery haphazardly placed. I dedicated several hours to organizing the breadboard, strategically shortening and repositioning wires. The objective was to design a protector with four open sides, utilizing standoffs for increased accessibility to switch out parts in the future. Given the significance of mobility for a distance sensor, a battery was incorporated, conveniently positioned next to the breadboard and easily switchable. Each wire was meticulously measured, elegantly cut, and bent to maintain a tidy and straightforward appearance. The visual representation of current flow in this model, in my opinion, might be more comprehensible and logical than a schematic diagram—direct visualization always aids understanding.

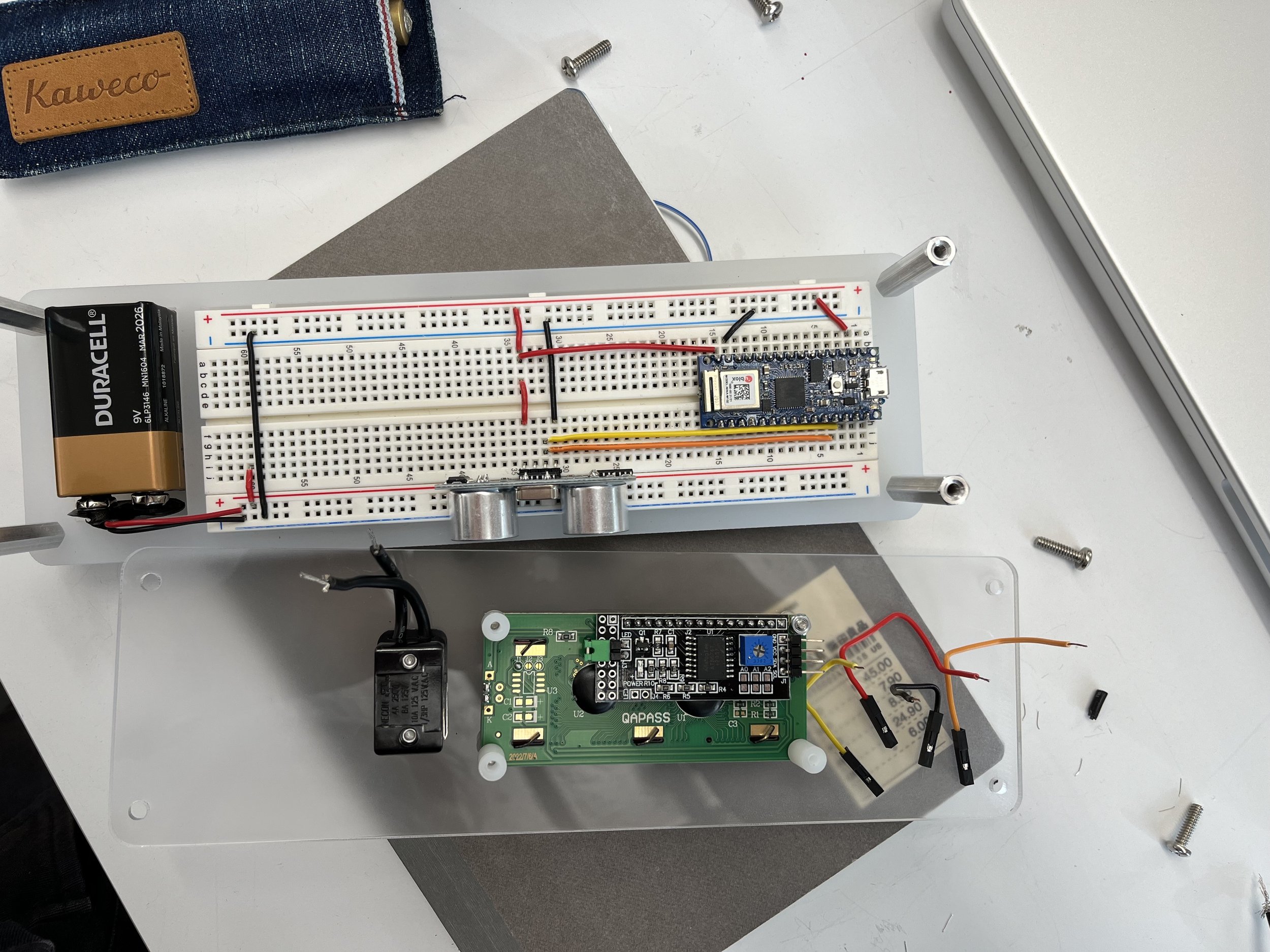

The dimensions of the breadboard and battery were measured using a digital caliper, and a holder was cut to stabilize them in the x and y axes. Both the base and the holder are made from 1/4" acrylic, a fortunate find in the shop. The display and toggle switch are securely fastened on top, with the digital caliper and laser cutter ensuring precise fittings. The caster wheels, while not the most ideal initially, underwent adjustments. Originally, I attempted to place them on a base with the same dimensions as the holder, but it was prone to tipping due to its narrow width. Consequently, I widened the base and utilized screws to secure the bed in position.

figure 1 - original setup: power from a usb

figure 2 - upgraded setup: power from a 9V battery

figure 3 - process of tidying

figure 4 - testing different outlet positions

figure 5 - holder is cut, standoffs are installed

figure 6 - battery can be easily swapped out

figure 7 - testing toggle switch and display

figure 8 - top is cut, switch and display are on

figure 9 - ready to work on the wires for the display

figure 13 - the piece is finally assembled

figure 19 - wheels are too close to each other

figure 10 - perspective view I before moving on

figure 14 - details

figure 20 - it worked, but not ideal

figure 11 - perspective view II before moving on

figure 15 - details

figure 17 - details

figure 21 - upgraded base — wider, same length

figure 23 - final product

figure 12 - wires for the switch and display cut

figure 16 - details

figure 18 - original idea for wheels

figure 22 - screws can help to position and stabilize the holder

figure 24 - final product

Conclusion

This project demanded a significant investment of time and intellectual effort, yet I genuinely relished the entire process and the resulting outcome.