TRANSLUCENT CONCRETE

Concrete and Optical Fiber

Fall 2022

Course: Fabrication

Instructor: Ben Light

Introduction + Implementation

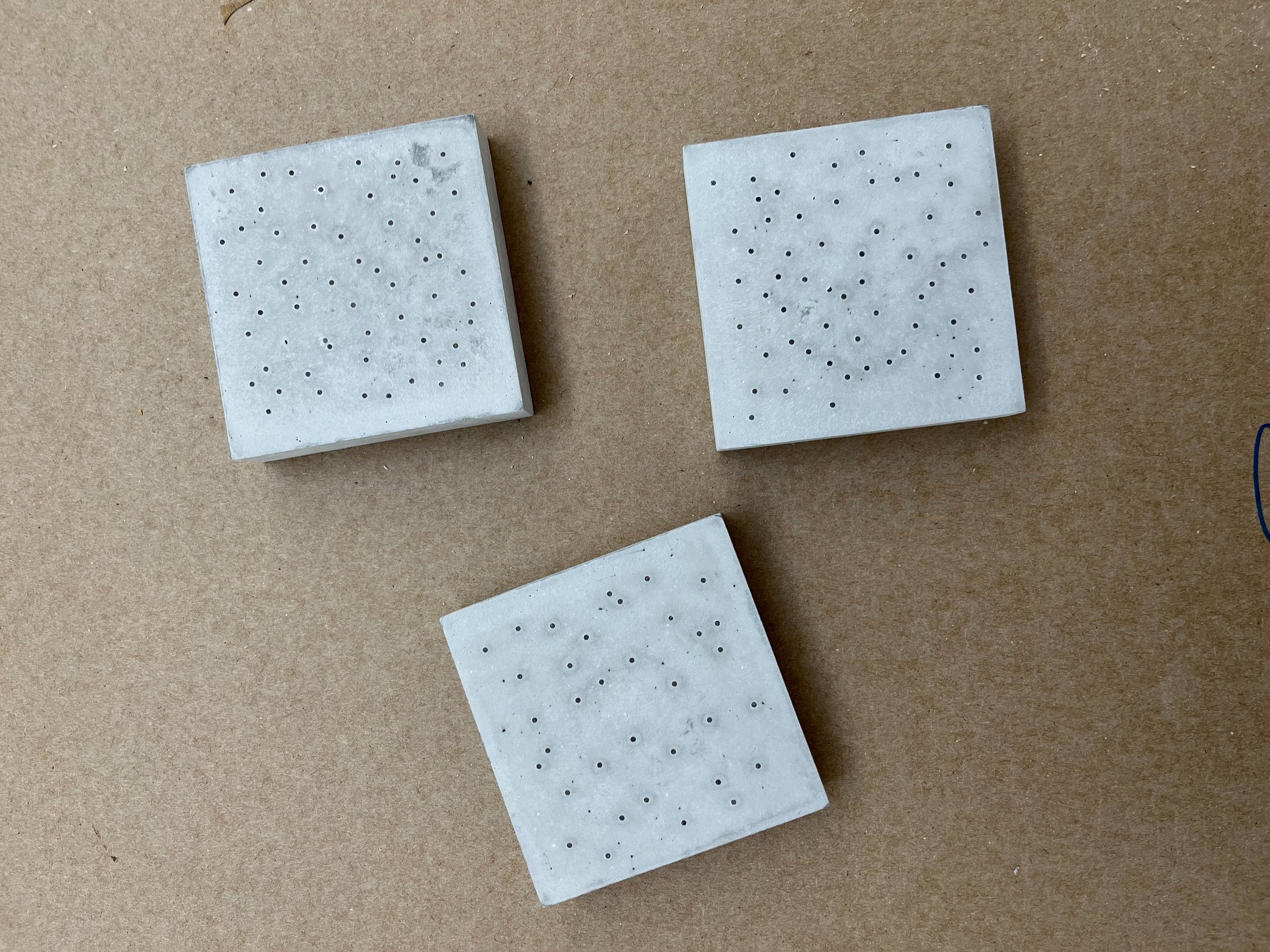

In this project, we were tasked with crafting one item repetitively. I decided to create a set of 5 beverage coasters using Rockite, incorporating optical fibers to depict constellations or stars.

Personally, crafting molds is always the most challenging aspect. They must strike a balance – not too sturdy, preventing them from breaking afterward, yet not too flimsy to avoid bending or leaking. I opted for plywood sheets due to their affordability, ease of cutting, gluing, and breaking.

Rockite was chosen based on the project's size; the coasters aimed for dimensions of roughly 3.5” x 3.5” x 0.5”. Rockite offers smoother finishes than concrete (to the best of my understanding) and sufficient strength. The selected optical fibers were 0.06” / 1.5mm in diameter, and I used white craft foam as a base for easy insertion of optical fibers. Since I worked on this project at home with limited space, I made and poured six molds separately. The advantage of this method was better control and precision in the process.

figure 1 - 3.5” x 7” plywood slats

figure 2 - slats were cut and sanded

figure 3 - ready to get glued

figure 4 - walls of the mold, made an extra one just in case

figure 5 - white foam, the base of the molds

figure 6 - blue tape: prevent leaking + provide stability

figure 7 - ready for optical fibers

figure 8 - optical fibers are cut and randomly inserted into the foam

figure 9 - 0.75lbs Rockite to 3.0oz water

figure 10 - precise measurement of water

figure 11 - precise measurement of Rockite

figure 13 - all are poured elegantly without leaking

figure 15 - harder than I expected, especially the foam part

figure 17 - before sanding

figure 19 - round 2 sanding, 600 grit

figure 21 - final product, but with some imperfections on some edges

figure 23 - top view

figure 25 - top view 2

figure 12 - mixing

figure 14 - step 1 of taking it out

figure 16 - molds were successfully removed

figure 18 - sanded by palm sander, 80 grit, surfaces were flattened

figure 20 - round 3, 2000 grit (might be unnecessary)

figure 22 - side view

figure 24 - bottom view

figure 26 - bottom view 2

Conclusion

The overall result was satisfactory, aside from some oversights during the sanding process with a palm sander, causing it to spin a bit too fast. The bottom still exhibited the foam texture, which I hope to improve for a smoother finish. I considered using a piece of American cheese for holding the optical fibers due to its smooth surface, but it turned out to be too thin. The visible wood grains on the sides were appreciated for their beauty.

In conclusion, crafting one piece multiple times was an excellent practice. The repetition significantly boosted my confidence, and with each iteration, I became more experienced, refining my approach and skills.